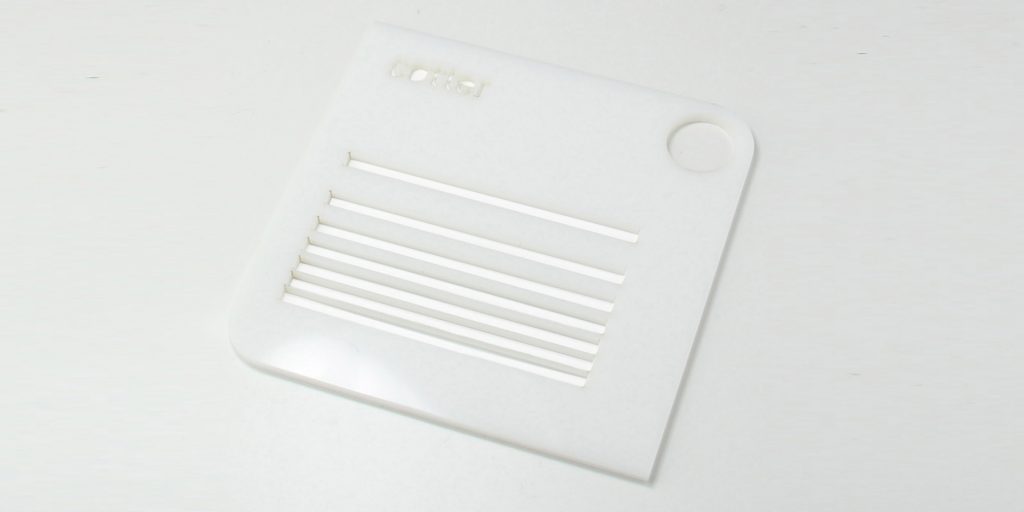

White acrylic

White acrylic with two glossy sites. GS.

1 mm is matte in the front, and the back is rough, and not suitable for visual display.

Facts

Technical description: Polymethylmethacrylat (PMMA) Hvid WH01/WN297

Weight: 1,18 g/cm3

Tolerance, thickness: +/- 15%

| Thickness | A4 | A2 | A1 | 3 mm | € 7 | € 24 | € 43 |

|---|---|---|---|

| 5 mm | € 11 | € 40 | € 72 |

| 10 mm (cast) | € 22 | € 78 | € 142 |

All sizes are in cm. All prices are inclusive of 25% VAT

| Thickness | 200×100 |

|---|---|

| 3 mm | € 116 |

| 5 mm | € 194 |

| 10 mm (cast) | € 387 |

All sizes are in cm. All prices are inclusive of 25% VAT.

Useful to know

Acrylic is often used for signage, jewellery, windows, screens, lids, furniture and aquariums.

Our acrylic sheets generally have a protective film on both sides to help prevent burn marks. If the sheet is only to be laser cut, we leave the film on. If the sheet is to be raster engraved, the film is removed from the side that is to be engraved.

Vector and raster engraving

Raster engraving of acrylic produces a matte, white surface, as the laser etches very dense lines in the material. The contrast is most visible in cast acrylic. A thin line of about 0.2 mm is drawn when vector engraving.

Laser cutting

Top – No burn marks. In general, a protective film is applied that should be removed after you have received your cutting. Has a clean, sharp appearance. When raster engraving, the film should be removed before cutting. The cutting process will create a matt, white deposition of smoke close to the cutting edge.

Edges – No burn marks. Have a sharp appearance and are in the same colour as the actual material. OBS! The laser will make the inside of sharp corners and curves turn a darker colour.

Bottom – No burn marks. Has a clean, sharp appearance. In general, a protective film is applied that should be removed after you have received your cutting.

Finishing treatments

When heated, acrylic can be bent for products such as hinges. You will get the best results by using a bendable template (can be made in i.e. MDF) and a hair dryer or other means of heating up the material first.

You can write on acrylic with whiteboard markers and magic markers.

Acrylic can be cleaned with soap and water.

Contact adhesive or epoxy can be used if the material is to be assembled with the same or other materials.